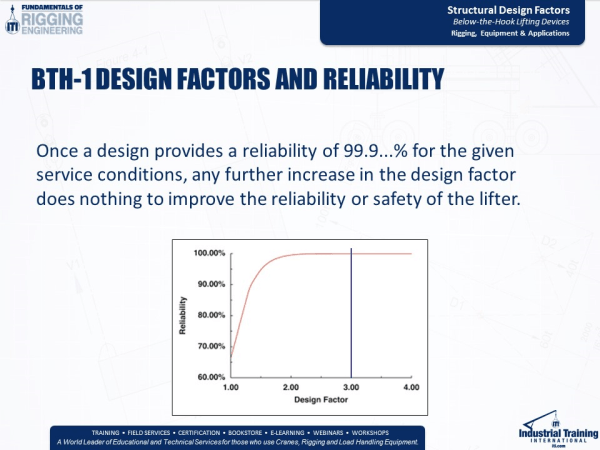

Variations in the design of the multi lift spreader bar evolve over a period of time as requirements and technology change and the demand for a more efficient product is desired.

Spreader beam design software.

How to design a spreader bar.

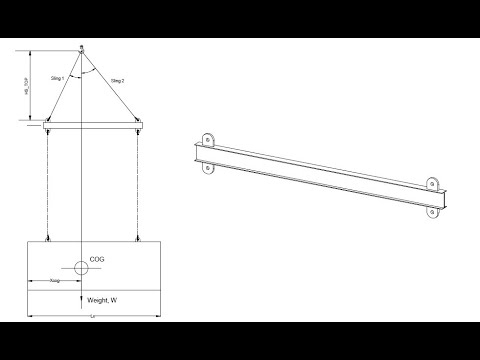

Spreader suspended by a sling often has the advantage over a lifting beam.

The beam was designed to deal with compression not bending.

In this the beam is suspended from a sling connected part way along the beam rather than at the ends.

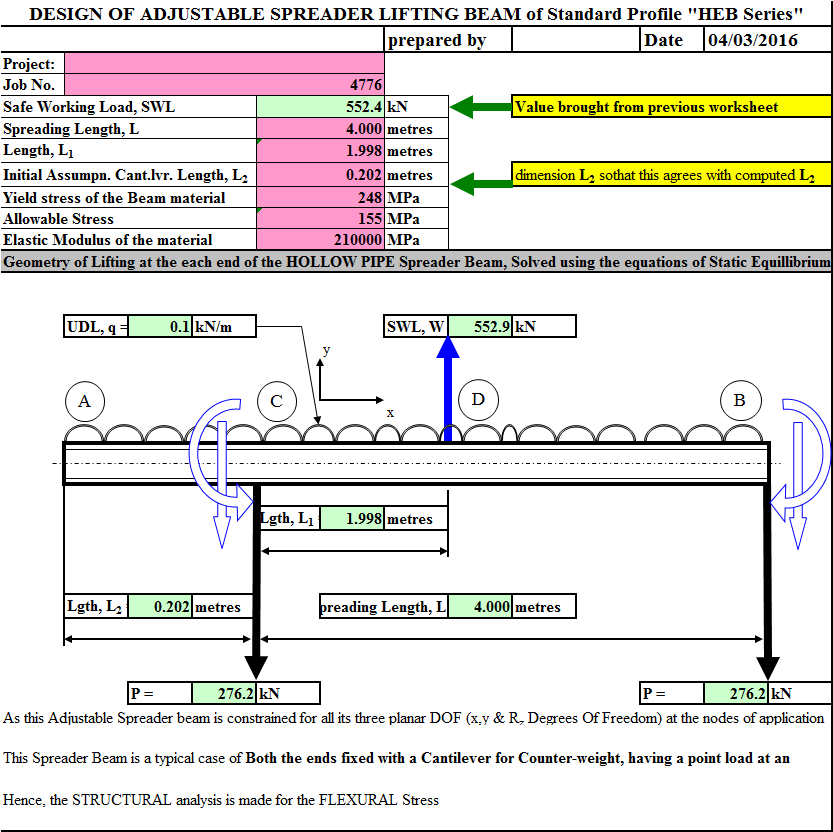

Design of adjustable spreader lifting beam of standard profile heb series geometry of lifting at the each end of the hollow pipe spreader beam solved using the equations of static equillibrium a strength design design for flexural bending stress selecting the section initially based on this.

Sparta s approach to optimizing the spreader bar design otherwise known as lifting bar or lifting beam is an iterative process.

In this article we will explore the design of a basic spreader beam and see what design checks are needed to establish the suitability of a spreader beam for particular lifting operation.

Alternatively the combination design previously referred to can be used.

Ce marked and certified to all global industry standards.

As a result a spreader beam will likely fail if it is not used correctly remember it is 3 to 4 times smaller than a lifting beam.

Spreader beams designed to direct load to top rigging and hooks requires a greater amount of headroom than a lifting beam.

Problems occur when a spreader beam is treated as if it were a lifting beam.

It increases the a dimension and the forces in the beam are a combination of bending and.

Custom design and off the shelf options available.

Spreader beams are universally applied gear which is widely used in various types of lifting operations onshore and offshore.

Misuse of these beams is shockingly common and still happens regularly in.